High Strength Steels

Kromite® Econo-Finish

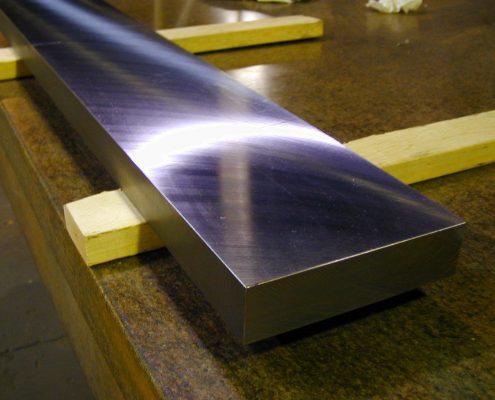

Pre-Hard, 28/34 RC, Decarb-Free, Plate

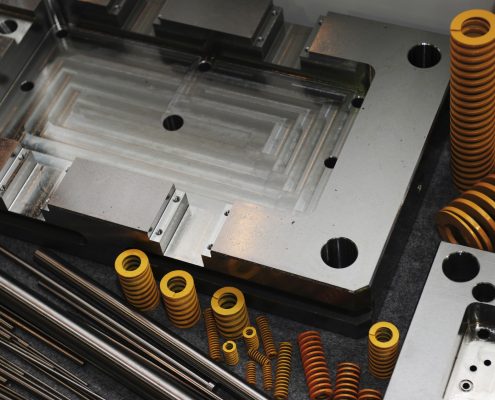

Kromite Econo-Finish is a modified 4140/4142 steel. Typical hardness is 269/341 BHN. This is a high strength alloy, furnished pre-machined (blanchard ground top and bottom) ready for your finish machining. This pre-hardened, pre-machined product will reduce material preparation time and allow you to get your finished parts into service quicker and extend service life.

All of the decarb (from the heat treating process) has been removed. This “decarb-free” surface finish will accept maximum surface hardening for maximum wear resistance. The PLUS TOLERANCE is provided to minimize machining at your job site.

Consider this product for dies, molds, support tooling, and various fixtures. Please inquire with your “finished” dimensions. Call or email us for a quote.

sPACKING

Features

Heat Treated

High Strength

4140/4142 (Mod.) Alloy

Furnished 269/341 BHN

Decarb-Free

Machinable

.

Lengths

10/12 Ft. R/L and Custom Cuts

Surface Condition*

Ground Top and Bottom – (+.015″/+.035″ oversize)

Sides Saw Cut – (+1/8″)

Length Saw Cut – (+1/8″ oversize)

Surface Finish – RMS 125 or better

*As delivered (pre-machined condition)

Available Stock

Squares and Flats

(Contact office for all inquiries.)

Also available in the Annealed Condition.

.

Typical Mechanical Properties

| Hardness, Brinell | 269/341 BHN |

| Tensile Strength | 156,000 P.S.I. |

| Yield Strength | 123,500 P.S.I. |

Thermal Treatment *(Pre-Hard)

Tempering – No tempering should be required, since the product is furnished to you in the pre-hardened condition (269/341 BHN). If you anticipate re-hardening to a higher hardness, inquire on our annealed product.

Annealing – Heat slowly to 1,500°F and hold for 1/2 hour per inch of thickness. Furnace cool at 20°F per hour to 1,230°F; air cool to room temperature. Expected hardness is 220 BHN.

.

Thermal Treatment *(Annealed)

Annealing – Heat slowly to 1,450/1,500°F and hold for 1/2 hour per inch of thickness. Furnace cool at 20°F per hour to 1,230°F; air cool to room temperature.

Hardening – 1,550/1,580°F – Temper immediately. Do not let temperature fall below 1,475°F between the hardening temp and quenching.

Typical Temper

Oil Quench from 1550°F

@ 500°F temper yields approx. Rockwell 50 “C”

@ 900°F temper yields approx. Rockwell 40 “C”

@ 1,000°F temper yields approx. Rockwell 30 “C”

* Above values are typical and are not guaranteed.