Industrial Polyethylene

Poly-Krome™

UHMW (Ultra-High Molecular Weight)

Poly-Krome™ is a highly versatile industrial polyethylene that exhibits excellent performance properties where chemical attack, noise reduction, abrasion, energy absorption and weight are key factors. It offers a good economical solution for a wide range of maintenance applications to reduce overall downtime costs.

Poly-Krome™ is utilized in a variety of industries including food processing, material handling, marine, pulp & paper, wastewater treatment, mining & quarry, automotive, steel & iron, pharmaceutical and agricultural.

This and other similar family of products can be produced in a variety of shapes, sizes and configurations depending upon the specific application.

.

Features

Chemical Resistance

Abrasion Resistance

Noise Resistance

FDA and USDA Accepted

Low Moisture Absorption Broad Temperature Range

Use Low Coefficient of Friction

Self Lubricating

High Impact Strength

Light Weight

Ease of Fabrication

.

Available Shapes

Rounds, Plates, Sheets, Tubing, Channels, Extruded Profiles, Strips and Squares (Cut from Plate)

*fabrication services upon request

.

Applications

- Bushings

- Wear Strips

- Sprockets

- Guide Rails

- Pillow Blocks

- Star Wheels

- Gears

- Rollers

- Mixer Linings

- Dock Fenders

- Truck Liners

- Timing Screws

- Bumpers

- Chutes

- Skirtboards

- Belt Guides

- Sleeves

- Hoppers

- Wear Pads

- Machine Parts

- Conveyor Tracks

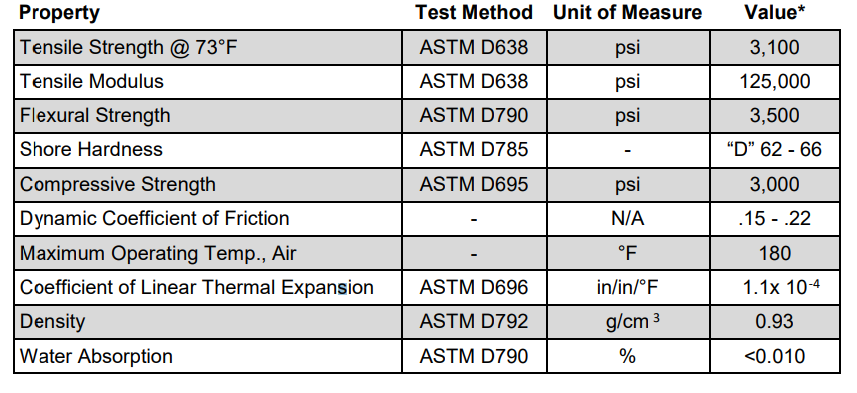

Typical Properties*

*Values presented are for virgin (natural) material only. Certain properties may vary for other like-family products. Information listed is based upon best of knowledge, experience and general testing.

.

Material Selection Table

- Natural – white color, multi-purpose maintenance applications including direct food contact, USDA/FDA Approved.

- Reprocessed – black or green color, (flecks of color throughout), economical benefit in non-food applications.

- Mine Plate – blue color, excellent wear and impact resistance, good for material handling maintenance applications.

- Anti-Static – black color, electrical conductive to reduce static build-up.

- Oil-Filled – grey color, reduced coefficient of friction, may be used in direct food contact, USDA/FDA Approved.

- UV Stabilized – black color, life may be extended up to 5x times in outdoor maintenance applications.

- Ultra – orange color, superior wear resistance, dimensional stability and UV protection.

- Premium – lime green color, combination of virgin and premium additives for severe sliding abrasion applications.

Chemical Resistance Table

| Acetic Acid | √ | Boric Acid | A√ | Ferric Chloride | A√ | Hydrogen Sulphide | √ | Sea Water | √ |

| Acetone | √ | Citric Acid | √ | Flourine | X | Lactic Acid | √ | Sodium Chloride | 10√ |

| Acrylonitrile | √ | Cyclohexanol | √ | Formaldehyde | 40√ | Mercury | √ | Sodium Hydroxide | 60√ |

| Allyl Alcohol | 96√ | Diesel Oil | √ | Formic Acid | √ | Methanol | √ | Sulphuric Acid | 75√ |

| Aluminum Chloride | A√ | Dioxane | √ | Glycerine | √ | Petroleum | √ | Tetralin | √ |

| Benzyl Alcohol | √ | Ethanol | 96√ | Hydrogen Acid | √ | Phenol | √ | Urea, aqueous | 33√ |

| Bleach (Chlorine) | X | Ethyl Acetate | √ | Hydrogen Peroxide | √ | Phosphoric Acid | √ | Zinc Chloride | A√ |

Values obtained at room temperature. Number indicates concentration if <100%. A = Aqueous solution. √ Specimen is resistance. X = Specimen is not resistant. Above table represents only a portion of chemicals that may or may not be resistant.

.

General Machining Guidelines

Poly-Krome™ can be machined with standard equipment that is generally used for fabricating metal and wood. Tooling that is sharp with wide-tooth spacing should be considered for proper chip clearance and heat removal. For specifics on sawing, turning, milling, planning and drilling contact our office. Caution should always be exercised. Use equipment that is in good condition. Utilize experienced operators. Appropriate safety gear should be worn.

For a downloadable PDF flyer for our Poly-Krome™ click on the button below