Tool Steels

Molex® #8

AIR HARDENING, WEAR RESISTANT DECARB-FREE TOOL STEEL

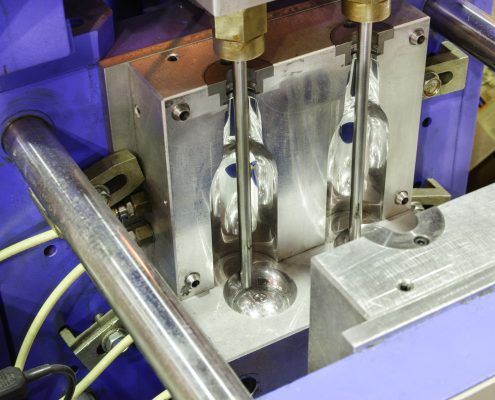

Molex#8 offers excellent wear resistance, combined with good deep hardening characteristics. Its ability to show low distortion or movement in heat treatment makes this material an excellent product for many tool room applications where size stability is critical. Consider this when specifications call out for AISI A-2 type tool steel. Typical applications include: plastic mold dies, stamping dies, machine parts, cold trimming dies, mandrels, slitters and threading taps. Call or email us for a quote.

Spacing

Key Features

100% Decarb-Free (Pre-Machined Oversize)

Excellent Machinability

High Compression Strength

Abrasion Resistance

Good Deep Hardening

Good Non-Deforming Properties

Typical Surface Condition*

- Ground Top and Bottom – (+.015”/+.035” oversize)

- Sides Saw Cut – (+1/8”)

- Length Saw Cut – (+1/8” oversize)

- Surface Finish – RMS 125 or better

*As delivered (pre-machined condition)

Spacing

Applications

- Blanking Dies

- Trimming Dies

- Master Hubs

- Forming Dies

- Gages

- Bending Dies

- Thread Rollers

- Punches

- Cutters

Available Lengths

10/12 Ft Random Lengths and Custom-Cut-To-Lengths

Available Sizes

1/2″ up to 5″ Squares

Spacing

Thermal Treatment*

Annealing – Generally furnished annealed. Raise to 1,550°F slowly, not to exceed 400°F/hour. Hold at temperature one hour per inch of greatest cross section (2 hour min.) Cool slowly in furnace. Do not exceed a cooling rate of 50°F/hour to 1,000°F. Cool to room temperature in furnace or air; 235 BHN max.

Forging – Pre-heat at 1250°F, then to 2000°F stop at 1700°F, cool slowly.

Hardening – 1,725°F/1,775°F, air quench to 150°F.

Preheating – 1,150°F /1,250°F, raise to temperature slowly, not to exceed 400°F/hour, then to 1300°F/ 1,400°F.

Tempering Chart

@ 350°F typical hardness Rockwell “C” 62.

@ 950°F typical hardness Rockwell “C” 48.

(Minimum time at tempering temperature is one hour per inch of thickness, even on thin sections. 2 hour minimum. Heavier sections should be held a temperature sufficient for uniformity of temperature.)

* Above values are typical and are not guaranteed.